The world of manufacturing is undergoing one of its biggest transformations in history. Gone are the days when factories buzzed with thousands of workers on assembly lines. Today, a new concept is gaining momentum: “Dark Factories.” These are fully automated facilities where machines operate without human presence—so automated that the lights can literally be turned off, since no workers need them.

This shift is not science fiction anymore. China, Japan, and parts of Europe are pioneering this futuristic model, aiming to boost efficiency, cut costs, and prepare industries for a new era of intelligent production. Let’s dive into what dark factories mean, why they matter, and how they’re shaping the future of global manufacturing.

What Exactly Are Dark Factories?

A dark factory is a manufacturing facility that operates 24/7 without human intervention. Robots, AI systems, and IoT (Internet of Things) devices handle every aspect of the process:

Raw materials are automatically loaded.

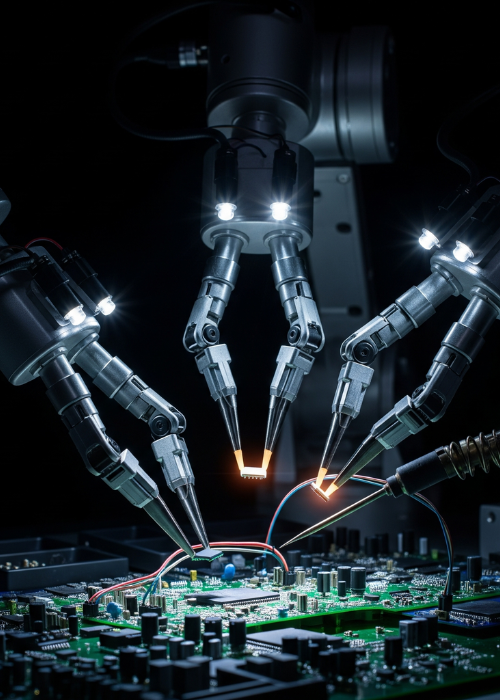

Robots assemble products with precision.

AI-driven quality control inspects outputs in real time.

Automated vehicles transport goods to storage or delivery stations.

Since there are no workers inside, lights, heating, and even air conditioning are unnecessary—hence the term “dark factory.”

Why Dark Factories Are Rising Now

Several factors are fueling the rise of dark factories:

Labor Shortages: Many industries struggle to find enough skilled workers, especially in manufacturing-heavy countries.

Cost Efficiency: Once set up, automation reduces labor costs, improves precision, and lowers error rates.

24/7 Production: Machines don’t need breaks, meaning factories can run non-stop.

Advanced Robotics & AI: Today’s robots are more adaptable and AI can manage complex tasks once reserved for humans.

Global Supply Chain Pressures: Countries like China are pushing automation to stay competitive and reduce dependence on outside labor.

Benefits of Lights-Off Manufacturing

Dark factories bring enormous potential to industries:

Productivity Boost:

Robots and AI enable continuous, around-the-clock production with minimal downtime.Higher Precision & Quality:

Automated systems reduce human errors, ensuring consistent quality control.Cost Reduction:

No need for wages, lighting, or climate control in unmanned facilities.Safety Improvements:

Dangerous tasks are handled by machines, keeping human workers out of harm’s way.Scalability:

Once programmed, automation can be replicated across multiple plants, making global scaling faster.

Challenges and Concerns

But dark factories aren’t without hurdles.

High Setup Costs: Building a fully automated facility requires massive upfront investment.

Job Displacement: Workers risk losing employment opportunities as machines replace human labor.

Complex Maintenance: Machines still need skilled engineers to manage breakdowns and updates.

Cybersecurity Risks: As factories become connected through IoT, they are more vulnerable to cyberattacks.

Ethical Questions: Should societies prioritize cost efficiency over jobs? How do we reskill workers for the AI-driven economy?

China Leading the Dark Factory Revolution

China, often called the “world’s factory,” is heavily investing in automation to address rising labor costs and global competition. Major Chinese tech and manufacturing companies are experimenting with fully robotic plants, where AI-powered robots perform everything from assembly to packaging.

Electronics production lines are testing completely unmanned operations.

Automotive manufacturers are using robotic arms and autonomous guided vehicles (AGVs) for 24/7 production.

AI-driven data platforms monitor machinery in real time, predicting failures before they occur.

The government’s “Made in China 2025” initiative directly supports this shift, positioning China as a global leader in smart manufacturing.

The Human Role in a Dark Factory World

While these factories minimize human presence on the shop floor, humans are still essential—just in new ways. Instead of performing repetitive manual tasks, workers may transition into roles such as:

Robotics Engineers (designing and maintaining machines).

AI Data Analysts (optimizing production algorithms).

Cybersecurity Specialists (protecting digital factory systems).

Product Designers & Innovators (creating what machines will build).

Thus, dark factories aren’t about eliminating humans completely, but about shifting their role from execution to innovation and oversight.

Future Outlook: Are Dark Factories the New Normal?

Dark factories represent a bold leap forward for the manufacturing world. The trend is clear: more countries will experiment with fully automated plants, particularly in electronics, automotive, and consumer goods.

In the next decade, we may see hybrid models where humans and robots work side by side. Fully “lights-off” operations will likely dominate in industries requiring precision and speed, while human creativity and flexibility remain valuable in design and innovation.

The question is not whether dark factories will spread—but how societies and businesses will adapt to this automation-first future.

Conclusion

The rise of dark factories is rewriting the rules of production. With benefits like 24/7 productivity, precision, and reduced costs, it’s easy to see why companies are rushing to adopt them. Yet, the shift comes with challenges—especially for workers whose jobs may be disrupted.

The future of manufacturing won’t be about humans versus machines—it will be about humans and machines together, each focusing on what they do best. As automation grows, the real test will be how well we manage the transition into this new industrial era.